Features

Vertical Farming to benefit from airlift pump tech

Collaboration between the University of Guelph and FlorNergia Inc. seeks to save energy and maintenance costs for growers.

July 28, 2022 By Logan Caswell

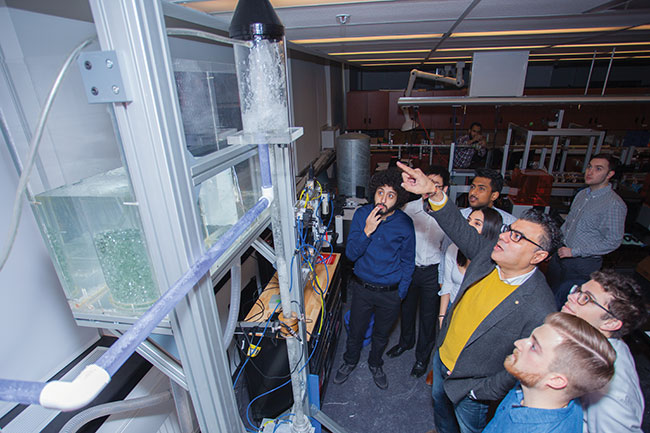

“Although the technology of the traditional airlift pumping system had been around since the 19th century, it had not been applied to industrial applications. Photo Courtesy of Wael AAhmed

“Although the technology of the traditional airlift pumping system had been around since the 19th century, it had not been applied to industrial applications. Photo Courtesy of Wael AAhmed New water pump technology currently applied in the aquaculture sector could mean savings in energy and maintenance costs for growers in the controlled environment agriculture sector thanks to a collaboration between FloNergia and the University of Guelph.

Based in Burlington, Ont, FloNergia Inc. was incorporated in 2016 to offer sustainable solutions for moving fluids using less energy. The innovative, patented “FloMov” airlift pump technology was developed with the engineering expertise at the Gryph Energy Lab at the University of Guelph (UofG) with support from the Research Innovation Office and funding from the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), and is currently being sold to and used in the aquaculture and wastewater markets around the world, including the USA, Germany, Australia, India as well as at home in Canada.

“The technology was developed for one [part] of the food sector back in 2016, and we were focusing initially on aquaculture applications,” said Wael Ahmed PhD, P.Eng. Chief Technology Officer at FloNergia and a professor at UofG. “Now we are extending this…Now we are in the second phase of this technology and [looking at] how to really adapt this technology to indoor and vertical farming.”

The “FloMov” technology was born when Ahmed and his researchers identified the need to reduce the high costs involved in moving water together with the high expense of energy usage, maintenance costs and expensive and inefficient aeration costs when water quality needed to be improved by oxygenation.

Ahmed explained that although the technology of the traditional airlift pumping system had been around since the 19th century, it had not been applied to industrial applications due to its inefficiencies of needing two systems, one for aeration and one for water circulation.

FloMov however is one efficient system with no moving parts; it uses energy for the air supply only, which in turn circulates and aerates water simultaneously. This results in low maintenance costs and a positive environmental impact. In commercial aquaculture trials, farmers reported a 50 to 70 per cent saving in energy costs and a 40 per cent higher aeration efficiency. Ahmed explained this is a significant saving to growers who can spend up to $5,000 per acre on maintenance costs. “On a 100-acre farm, that is a huge part of their costs,” said Ahmed. “Giving [growers] the opportunity to use a very simple, low maintenance device…replacing other pumps is very appealing.”

Ahmed hopes to develop the application for vertical farming by modifying the existing technology to be utilized in a multi-stage airlift pump which can move water to higher and longer distances. He said the project already has two growers in Ontario who are supporting the project and will conduct trials in vertical farms this summer which will monitor the efficiencies of the systems for hydrating and oxygenating the plant roots and assist in the wastewater treatment at the facilities.

Print this page